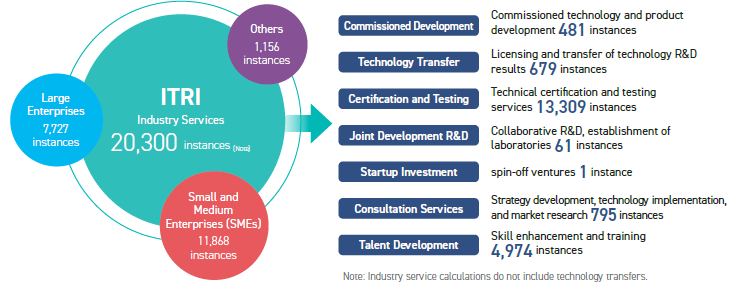

Against the background of rapid global industrial changes, ITRI plays a crucial role as both a "lever" and a "bridge". In response to industrial environmental trends, ITRI provides comprehensive R&D collaboration and consulting services, including commissioned development of new technologies and products, small-scale pilot production, process improvement, calibration and measurement, metrology standards, as well as technology transfer and intellectual property value-added services. By integrating domestic and international resources through diversified cooperation models, the Institute assists enterprises in overcoming technological bottlenecks and enhancing competitiveness. ITRI has simultaneously established the Tron Future Tech and an incubation mechanism to actively promote innovation, research and development as well as new business incubation. This accelerates the adoption of technologies and is dedicated to creating an industrial ecosystem with both flexibility and resilience. This approach responds to the uncertainties and diverse demands of the global market, driving Taiwan's industries toward sustainable development and realizing a future vision of technology-driven social progress.

Through technology transfer and application of research achievements, ITRI has successfully transformed its R&D capabilities into industrial value and promoted the upgrading and transformation of domestic enterprises. The Institute develops key technologies to support Taiwan in achieving its net-zero emissions target based on the "2035 Technology Strategy & Roadmap." Simultaneously, ITRI adopts a collaborative R&D model and works closely with domestic and international enterprises and research institutions to promote industrial innovation; it supports startup teams, advances technology commercialization, and expands the impact of R&D results. Through corporate consulting and talent training services, the Institute deepens technology application and strengthens industrial resilience. These achievements have not only driven industrial upgrading and social development but also enhanced Taiwan's global competitiveness and helped the country become a vital force in driving industrial innovation.