Continuous water quality monitoring technology and intelligent transformation and upgrading of production water management. Smart water quality monitoring technology helps the metal processing industry achieve zero discharge water exceeding the standard and reduce carbon emissions by 10%.

|

Environmental (E)

|

Social (S)

|

Economic (E)

|

|

Zero exceedance of metal processing effluent standards to prevent environmental pollution.

|

Reducing manual meter reading and hazardous environment operation time by 50%, ensuring employee work safety.

|

Internal controls comply with environmental regulations to prevent effluent exceeding standards that could lead to work suspension.

|

|

Solutions

|

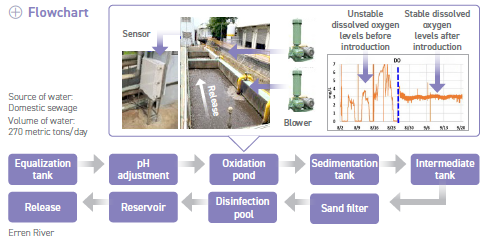

Developing long-lasting anti-biofilm water quality sensing technology and introducing smart low-carbon water quality monitoring technology. By using water quality sensors to feedback and control the flow ratio of high-concentration waste liquid and the aeration volume of the biological pool, zero exceedance in effluent discharge standards has been achieved and carbon emissions from water treatment have been reduced by 10% per plant.

|

|

Technology Application

|

By developing anti-biofilm technology, the rate at which microorganisms and contaminants adhere to water quality sensors in sewage is mitigated, achieving accurate continuous measurement and extending the manual maintenance cycle by more than four times.

By developing a composite water quality sensing system technology, it is possible to provide continuous six-in-one sensing of copper ions, chemical oxygen demand, suspended solids, pH, conductivity, and water temperature. Additionally, seven types of pattern recognition for water quality signal have been developed to assist in automated water quality anomaly warnings, eliminating the burden of manual interpretation.

|

|

Achievements

|

Assisted leading manufacturers of metal processed products (such as server guide rails and automotive fasteners) in implementing smart low-carbon water quality monitoring technology. Supported the mixing and homogenization of high-concentration waste liquid, aeration control in biological oxidation ponds, and continuous water quality monitoring before discharge. Achieved zero exceedance of effluent standards and reduced carbon emissions from water treatment by 10% per plant.

Assisted the Environmental Protection Bureaus of Taichung City Government and Kaohsiung City Government in continuous monitoring of urban river water quality to prevent public panic caused by fish kills; assisted high-density aquaculture operators in monitoring water quality changes after feeding to avoid excessive accumulation of organic matter in ponds, which could lead to accidental losses.

|